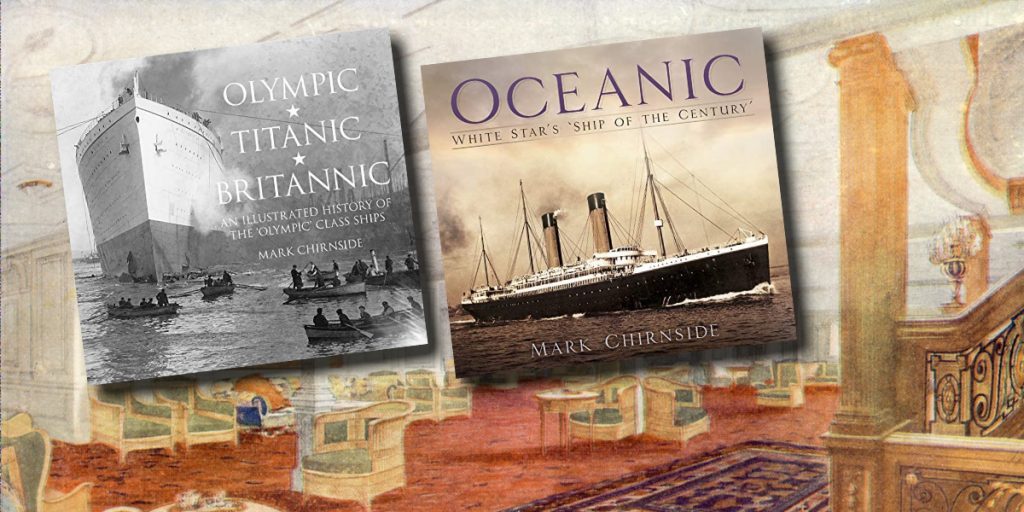

Welcome to the official website of maritime author and historian Mark Chirnside

Olympic, Titanic, Britannic, Majestic, Aquitania and other liners of the past.

‘Extraordinarily researched … highly recommended.’

‘Once you see the author’s name on the cover, you know it’s worth buying.’ ‘Awesome book...’

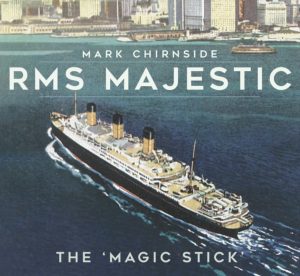

The revised and expanded edition of Mark Chirnside’s RMS Majestic: The ‘Magic Stick’ was released 7 March 2024. Signed copies are available to order securely through this website!

Featured Articles from Mark’s Article Page |

Contrary to popular belief, J. P. Morgan did not finance construction of the ‘Olympic‘ Class Ships. Olympic, Titanic & Britannic: An Issue of Finance (external link) explains in detail how the White Star Line raised the capital, mortgaging their own fleet in the process |

This dossier of evidence about Titanic‘s Centre Propeller includes my detailed video presentation of the primary sources about the doomed liner’s propeller specifications and links to articles analysing the available evidence, as well as video commentary from Bill Sauder and Ken Marschall. Contrary to decades-long popular assumption, Harland & Wolff’s own records document that her propeller specifications differed from her older sister Olympic |

Britannic: The ‘Length and Breadth’ of the Ship dispels common myths about how long Britannic was and why she was slightly wider than her sister ships |

This site has been developed to make my books available and to showcase some of my latest maritime history research. I specialise in detailed research of archival material, and in giving research into the ‘Olympic’ class liners a broader perspective through detailed analysis of the broader picture, including many other liners that served in the White Star, Cunard, or other shipping companies of that period. If you have any questions, please contact me; please also make sure to subscribe to my blog on the Updates page; and to follow me on Twitter and Facebook for more updates on my upcoming projects.

Enjoy your visit!